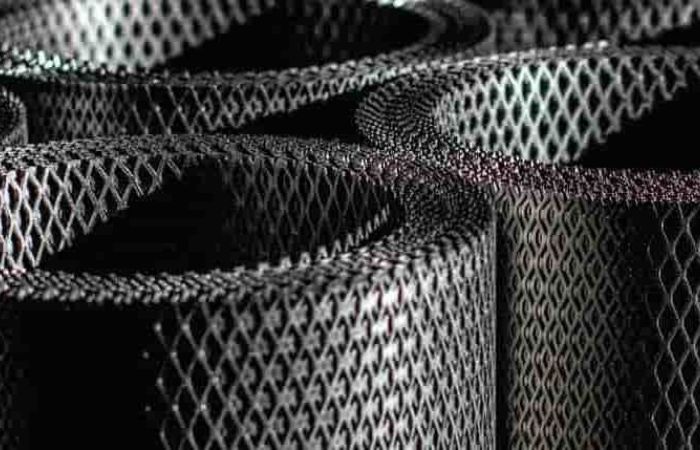

Expanded Mesh

Our extended mesh solutions provide a sensible, functional, and long-lasting answer to the difficulties of cooking in a busy kitchen. Expanded mesh is a porous metal material with a high surface polish and durability that can be used in a variety of applications.

Expanded mesh is a type of aluminum netting that can be used to cover an outdoor living area like a patio, deck, or pool. The netting is simple to use and available in a range of colors.

Expanded metal is a metal made from a single sheet by simultaneous cutting and drawing method, which allows to achieve a good strength and weight ratio.

Expanded Metal Mesh Has Many Uses

- It gives architects and clients unrestricted design space in open ceiling systems. To create diverse shadows and perspectives, various enlarged metal models can be employed.

- Different models are offered to meet a variety of requirements. Depending on the project's economy, design, and accessibility requirements, docking, hook-opening, corridor-type hook-opening, and down-scrolling technologies can be employed.

- Metals that have been expanded can also be utilized on facades and walls, where they can be merged into the ceiling.

- Expanded metal levy is thought to be heavy; however, contrary to popular belief, these goods are light. As a result, it provides the benefit of use. It is suitable for use in ladder constructions, cable plants, cabinet doors, and ceiling coverings.

- Expanded metal sheets are made from DKP aluminum and stainless steel, and they have high durability and low cost. The expanded metal standard may vary depending on the use.

- Today, expanded metal acknowledges several features in all aspects of various architectural projects in the construction business. It shines out in trekking locations, garden pairings, covers, and numerous Sunbreaker regions.

- Expanded metal products that adapt to modern structures and give life to designs that are not concerned with aesthetics are determined to be standards in the region to be examined. All of these sections are measured in millimeters and go through the manufacturing process.

- It is critical that the measurements are handled accurately because it is prepared in one piece without welding. Expanded metal patterns are thus inserted in places to fully comply with the structure's specifications.

- Cold rolling is the process through which semi-finished steel is given cold quality and made ready for the consumer by cutting and packing in the necessary revenge in the scissor lines.

- Cold rolled flat items are both expensive and have distinct traits in terms of production characteristics and production challenges.

We are one of the most reputable manufacturers and suppliers of Expanded Mesh. These goods have a wide range of applications.