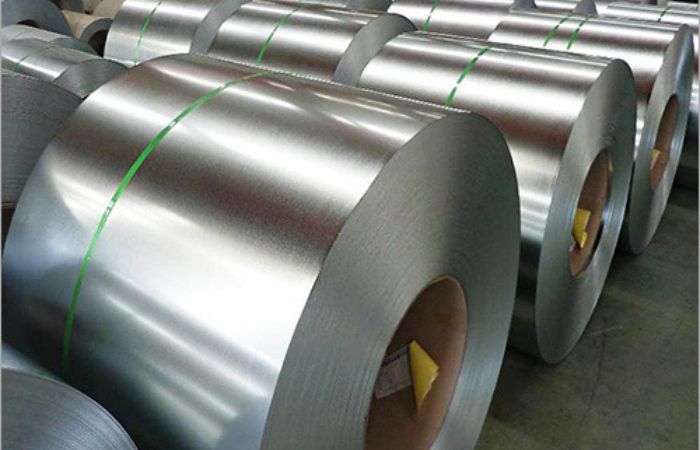

Aluminium Plain Coil: A Versatile Solution For Industrial Applications

A flat, rolled sheet of aluminium known as a plain aluminium coil is frequently used in industrial settings. These coils are created by rolling aluminium alloys, which decrease the material's thickness while increasing its length and width via a rolling mill. From 0.2 mm to 6 mm thick, aluminium plain coils are available in various thicknesses. These coils' widths can also differ, ranging from 1000 mm to 2000 mm or more. The coil's length can also be altered to fit the application's unique needs.

Here, Hk Enterprises offers you a complete reading period where you may discover everything there is to know about Aluminum Plain Coil. Therefore, if you want an aluminium coil, consider choosing us.

Advantages Of Aluminium Plain Coil

- The strength of durability

- Aluminium is a potent substance that resists rust, corrosion, and other types of disintegration. This translates to simple aluminium coils having a long lifespan and requiring little upkeep to remain in good shape

- Simple to maintain

- Aluminium simple coils need less upkeep than other materials because of their endurance. They can resist exposure to severe weather without deteriorating and don't need painting or other protective coatings.

- Thermodynamic efficiency

- Aluminum is a material that is extraordinarily recyclable and may be used repeatedly without losing its quality or qualities. This implies that plain aluminium coils can be recycled and used in new ways, making them a sustainable option.

- Lightweight

- Aluminium plain coils are lighter than other materials like steel or copper. In addition to lowering transportation costs and increasing usability in various applications, this makes them simpler to handle and move.

- High Flexibility

- Simple aluminium coils can be moulded to fit the application's requirements. They are a versatile material option for various industrial tasks since they can be cut, bent, and formed without losing strength or durability.

Aluminium Coil Sheet

A flat sheet of aluminium rolled coil is known as a plain aluminium coil sheet for easy storage and transportation. Aluminium ingots are often rolled through a mill to create the sheet, which increases the sheet's length and width while decreasing the thickness of the metal.

Once moved, the sheet is coiled into a roll to the proper thickness and width for more straightforward handling and storage.

Construction is one of the leading industries that use plain aluminium coil sheets. They are frequently used for gutters, downspouts, siding, roofing, and other architectural elements.

Owing to its resilience to corrosion and longevity, aluminium plain coil sheets are also employed in producing products like refrigerators and air conditioners.

Aluminium plain coil sheets offer a flexible, durable, and sustainable material option for various industrial applications.

Their strength, lightweight, and corrosion resistance make them the perfect material for the construction and industrial industries. Their recyclability makes them desirable for companies trying to cut waste and save the environment.

High Strength-To-Weight Ratio

Aluminium plain coils are solid and long-lasting despite being lightweight because they have a high strength-to-weight ratio. This quality makes them the perfect material option for constructions that need strength without adding a lot of weight.

Aluminium plain coils have a high strength-to-weight percentage, enabling them to lighten buildings without sacrificing strength, making them a desirable material option for aerospace, automotive, and construction sectors.

The unique characteristics of aluminium as a metal contribute to the high strength-to-weight ratio of aluminium plain coils.

Aluminum has a low density, making it lightweight and with high tensile strength, capable of withstanding a large amount of force before snapping. Furthermore, aluminium has a high modulus of elasticity, making it rigid and deformation-resistant.

Aluminium plain coils can give constructions the required strength and rigidity because of this mix of attributes without adding a lot of weight. For instance, aerospace companies usually implement plain aluminium coils to reduce aircraft weight and improve fuel efficiency.

Aluminium plain coils are used in the automobile sector to lighten vehicles, which enhances emission control and lowers pollution.

Aluminium plain coils are a powerful and appealing material choice for various applications due to their high strength-to-weight ratio. These qualities enable them to give structures the required rigidity and strength without adding weight, which can enhance efficiency, cut costs, and promote resilience.

Understanding The Importance Of Aluminium Plain Coil Thickness In Applications

When evaluating whether the plain aluminium coil suits a particular application, thickness is a crucial factor.

When choosing the best material for a given application, it is essential to consider the thickness of plain aluminium coils because it impacts the material's cost, performance, and durability.

Aluminium plain coil thickness can change according to the requirements and the specific use. The thickness of aluminium plain coils can vary from 0.2 mm to 6 mm.

Thinner aluminium plain coils, frequently used in applications requiring flexibility and formability like roofing and siding, gutters and downspouts, and appliance manufacturing, typically have a thickness of less than 1 mm.

In applications that demand strength and longevity, such as automotive parts, aerospace components, and structural applications, thicker aluminium plain coils are frequently employed, usually 1 mm and beyond.

Their thickness can also impact aluminium plain coils' weight and strength-to-weight ratio. Thicker aluminium plain coils are typically heavier and stiffer, while thinner locks are lighter and more flexible.Yet, more giant waves of aluminium can be advantageous in some situations since they offer more strength and durability than more delicate coils.

When choosing the ideal material for a particular application, the thickness of plain aluminium coils is crucial. The consistency must be selected depending on the application's needed qualities, including flexibility, strength, durability, weight, and price.

Applications Of Aluminium Plain Coil

Plain aluminium coils have numerous applications across various industries because of their distinctive characteristics like their lightweight corrosion resistance, lightweight and ease of forming.

Aluminium plain coils are frequently used for roofing and cladding in the building industry because of their durability and corrosion resistance. Because of their light weight and ease of shaping, they are often utilised to make windows and doors.

Aluminium plain coils are used to make engine parts, structural elements, and body panels in the automobile sector. They are chosen over more conventional materials like steel because they are lighter, which increases fuel efficiency and lowers pollutants.

Aluminium plain coils are widely used in the aviation sector for aircraft manufacturing because of their durability, lightweight, and corrosion resistance. They produce crucial parts for engines, wings, and fuselage.

Manufacturing electrical enclosures, panel boards, and insulators also use plain aluminium coils in the electrical sector. They are an excellent option for these applications due to their high electrical conductivity, resistance to corrosion, and ease of formability.

Aluminium plain coils are used in packaging to create components such as cans, foils, and containers. They are chosen over other materials because they are lightweight, flexible, and corrosion-resistant.

Overall, aluminium plain coils' versatility and unique properties make them an attractive material choice for various applications across several industries. Their use is expected to increase due to their sustainability, recyclability, and the growing demand for lightweight and eco-friendly materials.

HK's Aluminum Sheet Coil is produced in a variety of Alloy's following the Aluminum Association (AA) Specifications and in a range of tempers for use in preparing meals, tableware insulation, air conditioning fin, reflector, bus bodies, profiled building products for roofs and cladding, false ceiling, fascia, panelling packaging, general engineering purposes, and more.

We pride ourselves on being the top suppliers of aluminium polykraft coil in Bihar.

Cost-Effectiveness Of Aluminium Plain Coil

Aluminium plain coils are very useful and affordable compared to other materials like brass, copper, and stainless steel. Aluminium primary coils may initially cost more than other materials, but over time, they are more cost-effective because of their longevity, low maintenance requirements, and recycling potential.

The reduced maintenance needs of plain aluminium coils are one of the critical economic advantages. Because primary aluminium coils have high corrosion resistance, they don't require routine maintenance or repairs, which lowers maintenance expenses throughout the material's lifespan.

The excellent strength-to-weight ratio of plain aluminium coils is another cost advantage.

Because primary aluminium coils are lighter than other metals, they may be handled and installed more efficiently while transporting less. This further lowers costs because fewer plain aluminium coils are needed to provide the same strength as other materials.

Aluminium plain coils can also be melted down and used to create new goods because they are highly recyclable. Because of the decreased requirement for raw materials and the accompanying expenses, plain aluminium coils are a more sensible and economical choice.

Overall, the low maintenance needs, high strength-to-weight ratio, and recyclable nature of plain aluminium coils contribute to their cost-effectiveness. Thanks to these qualities, they are a desirable material option for various applications across numerous sectors.

The price of aluminium coils in India can vary based on several factors, such as the current market demand, the quality and grade of the aluminium coil, and the thickness and width of the coil; as per our pricing policy, we are supplying good quality products at an affordable rate.

You can choose us; we ensure that our company is reputable and reliable and can provide the necessary quality certifications and documentation for the aluminium coil. We are the best Distributors in India.

Our company stands out as the premier provider of aluminium polykraft coil in Bihar

We Supply Our Products At The Following Cities Of Bihar

Patna, Gaya, Purnia, Begusarai, Bhagalpur, Bihar Sharif, Darbhanga, Arrah ,Katihar, Munger, Chhapra, Mehsi, Danapur, Bettiah, Saharsa, Hajipur, Sasaram, Dehri, Siwan, Motihari, Nawada, Buxar, Kishanganj, Jamalpur, Jehanabad, Aurangabad.

Why Choose Us?

Making the most outstanding supplier choice can make the purchase profitable. The top supplier of plain aluminium coil in India is HK Enterprises. Customer satisfaction is our primary priority for us.

We offer premium goods that meet your needs and expectations at affordable pricing. Our customer support team is focused on meeting your needs and resolving any issues that may occur, and they are responsive and professional.

Our availability and delivery guarantee a prompt and timely supply of the products required to satisfy the schedules and deadlines of your project.

With our superior quality and exceptional customer service, we have established ourselves as the leading aluminium Plain coil suppliers in Bihar.

Read More: Aluminium Plain Coil Suppliers In Chhattisgarh